Chemical cleaning is to remove scales, deposits,or unwanted materials from process equipment, piping or any wetted/heated surface or any wetted or heated surface.

Chemical cleaning is to remove scales, deposits,or unwanted materials from process equipment, piping or any wetted/heated surface or any wetted or heated surface.

China Hot oil flushing pipeline service is the use of chemical agents, the temporary transformation of the pipeline, with temporary pipeline and circulation pump station from both ends of the pipeline to circulate chemical cleaning. This technology is flexible, has no requirements for the shape of the pipeline, is fast, and cleans thoroughly.

● Deposit removal

● Results in increased plant efficiencies

● Reduced operating costs

● Improve produced product

● Improve heat transfer

● Scales

● Deposits

Other unwanted materials on the surface of process equipment, piping, or any wetted or heated surface

Removal of fouling deposits by the action of chemical application

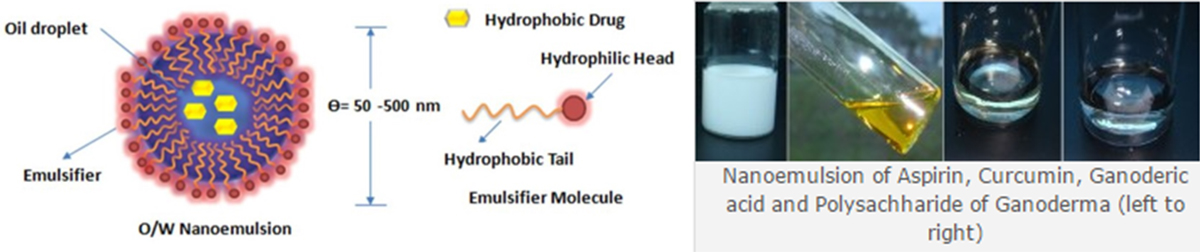

Removal can be cleaned through Solvent (e.g.Nanoemulsion )Cleaning – dissolve and remove- or chemical action - modification of physical properties of the deposit i.e. soften or dissolve

Long-term use of the pipeline, the oil and mud inside the pipe, rust and scale curing caused by the original diameter of the pipe become smaller; pipe sludge precipitation generated hydrogen sulfide gas caused by environmental pollution and easy to cause combustion and explosion; wastewater acid, alkali substances easy to produce corrosion of the pipeline wall; pipeline foreign matter is not regularly removed will cause the pipeline blockage, so the pipeline should be cleaned. After cleaning, a layer of dense chemical passivation film is formed on the clean metal surface, which can effectively prevent the re-emergence of dirt and can effectively protect the equipment from corrosion or other chemical damage, effectively ensuring the safety and extending the service life of the equipment.

Hydro Jetting or Retro Jetting is the application of high-pressure water at 5000-17000 psi using a line mole nozzle to move inside a pipe, dislodging and flushing mud, scale or construction debris from the internal surfaces of pipe work. This is one of the efficiency mechanical cleaning method to remove debris build up, scale and light deposits present in the general pipe work. Larger pipes require more water flow (energy) for the self-propelled line mole to move up the pipe and have sufficient flow to sweep the loose debris from the pipe being cleaned.

● - Hand Lancing

● - Line Moles

● - Heat Exchanger Bundle Cleaning

● - Water Knife

Coating Removal

● Boilers

● Heat Exchangers

● Feed water Systems

● Cooling Water Systems

● Fire Water Systems

● Lube Oil Systems

● Hydraulic Systems

● Pipelines

● Condensers

● Process Piping Systems

● Reactors

TimEast will be able to provide and support for the full range of high pressure retro-jetting equipment and tools to clean up the pipeline sizes 2" to 44".

Retro Jetting Equipment--High Pressure Pump & Retro Jetting Accessories

|  |  |  |  |  |

|  |  |  |  |  |

The primary aim of undertaking flushing to this standard is to remove contaminants and impurities from the control or lubricating fluids /hydraulic system that can affect the performance of the system, or indeed may affect the performance of components installed in a hydraulic system such as the Oil System.

It is particularly important when commissioning equipment like this that the initial clean is to the exacting standards set down and that procedure for cleanliness is followed in total detail.

Decontaminate hydraulic systems: lube oil, seal oil, control hydraulics, subsea controls, umbilicals prior to initial commissioning or following shutdown maintenance

Regular servicing of any hydraulic system and medium

-Trouble free start-up of systems

-Reduced unplanned and costly down time

-Clean systems extend bearing lifespans

-Continuous operations